Biopolus created the BioMakery, an urban metabolic hub, to integrate circular urban infrastructure and technology with open innovation, helping cities transition from their current linear system of consumption and waste, to a sustainable and regenerative circular model. The BioMakery was created based upon the principle of water-based urban circularity, where energy, food, and waste systems are built around a regenerative and sustainable water cycle.

The BioMakery is a production platform that produces intermediary products from wastewater and organic waste. These intermediary products can then be further processed to a wide scale of valuable end products such as reuse water, food and feed, biopolymers, etc.

What is a circular economy?

“A framework for an economy that is restorative and regenerative by design… It entails gradually decoupling economic activity from the consumption of finite resources, and designing waste out of the system. Underpinned by a transition to renewable energy sources, the circular model builds economic, natural, and social capital.”

Ellen MacArthur Foundation

WATER FACTORY

Via MNR technology, Biopolus has created a modular, expandable water treatment system for complex circular urban water treatment and management. Water from sewage, industrial processes, and urban waterbodies is treated to the most stringent regulations, perfectly safe to be released back into the environment. However, depending on the needs of the community, the water can be further processed to meet the specific criteria for numerous water products.

DIGITIZATION

As information and big data become more and more a part of our daily lives, ‘smart’ solutions are needed, which can integrate urban infrastructure with various data platforms and technologies. Biomakeries act as hubs for integrating high tech urban infrastructure with sustainable technologies and information platforms. The MNR technology of the Biomakery is the backbone of the hub, and is designed with an automated system for simple daily operation. The control unit ensures fast, efficient and professional intervention in the event of operational error. It also allows for seamless system upgrades, smooth adaptation in the event of facility changes, and straightforward integration with other informational technologies.

DESIGN & ARCHITECTURE

Biopolus integrates water recycling, biological manufacturing, energy recovery technologies, and community functions into the BioMakery, a modularly designed and architecturally compact facility. The modularity of the Biopolus system allows for flexible layout design, with vertical and horizontal architectural solutions, ensuring that the building can fit into any urban environment.

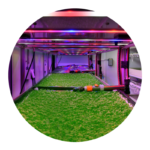

COMMUNITY

The beautiful garden-like atmosphere of the BioMakery fosters an environment for an open and lovable relationship with its surrounding community. Space for a visitor center can be included, where visitors, school groups, politicians, and professionals can visit the BioMakery to explore sustainable sciences and witness first-hand circular technologies and innovation. A larger space can also include: an auditorium for conferences, coffee shops featuring a salad bar with urban farmed greens, or even an entertainment area with art and water play.

EDUCATION / R&D

The BioMakery provides an Open Innovation Platform to integrate new, innovative technologies, making it an ideal place to study and develop circular solutions for the future city. Universities and businesses can collaborate in a living, learning laboratory, where they can work together to solve complex world problems. Partners in innovation can work together to develop all kinds of production platforms to create valuable end products from specific waste streams. The BioMakery can also become home to a university “Circularity Curriculum”, where students are able to study and experience innovative circular processes and technologies first hand. The students can work together alongside industry leaders, creating more opportunities for advances in innovation.

PLANT FACTORY

Biopolus has also developed a controlled urban farming factory system, called aero.green, which uses an integrated mixed system of three primary urban farming techniques: hydroponics, nutrient film technology (NFT), and aeroponics. The Biopolus plant factory is built using a modular system, one that is scalable and customizable, with optimized growth modules for each plant type. A specialized feeding and lighting schedule (with ideal wavelengths and intensities) is formulated for each crop, creating the highest quality product. Crop types can include specialty, exoctic produce (including microgreens and heirloom varieties), propagating material for open field agriculture, medicinal and cosmetic plants, and flowers.

BIOLOGICAL MANUFACTURING

Resource recovery means the fractionation of waste materials, with the aim of value-added material production. These materials, created through a biorefinery system, can be used as secondary (industrial) raw materials, or as final products, such as proteins, cellulose, and other bio-polymers, compost, fertilizer, etc. Biorefining includes the fractionation of biomass into various products that can undergo further biological, (bio)chemical, physical and/or thermal chemical processing and separation to create value-added products from organic and green waste. A BioMakery biorefinery system combines technologies currently applied in practice, enabling the synergistic effects of the various connections.

ENERGY RECOVERY

A circular city of the future needs a sustainable energy model to power urban systems. Renewable energy and energy efficiency are sometimes called the “twin pillars” of a sustainable energy policy, and both are crucial for the future city. In designing a BioMakery, Biopolus performs the metabolic mapping of material and energy flows for each development, specifically looking for waste to resource opportunities, synergies within the facility and with outside neighboring areas, and opportunities for innovation and optimization. This allows each BioMakery to maximize energy recovery and generation opportunities for use at the facility and its surroundings, while also minimizing the energy needed to run the facility.