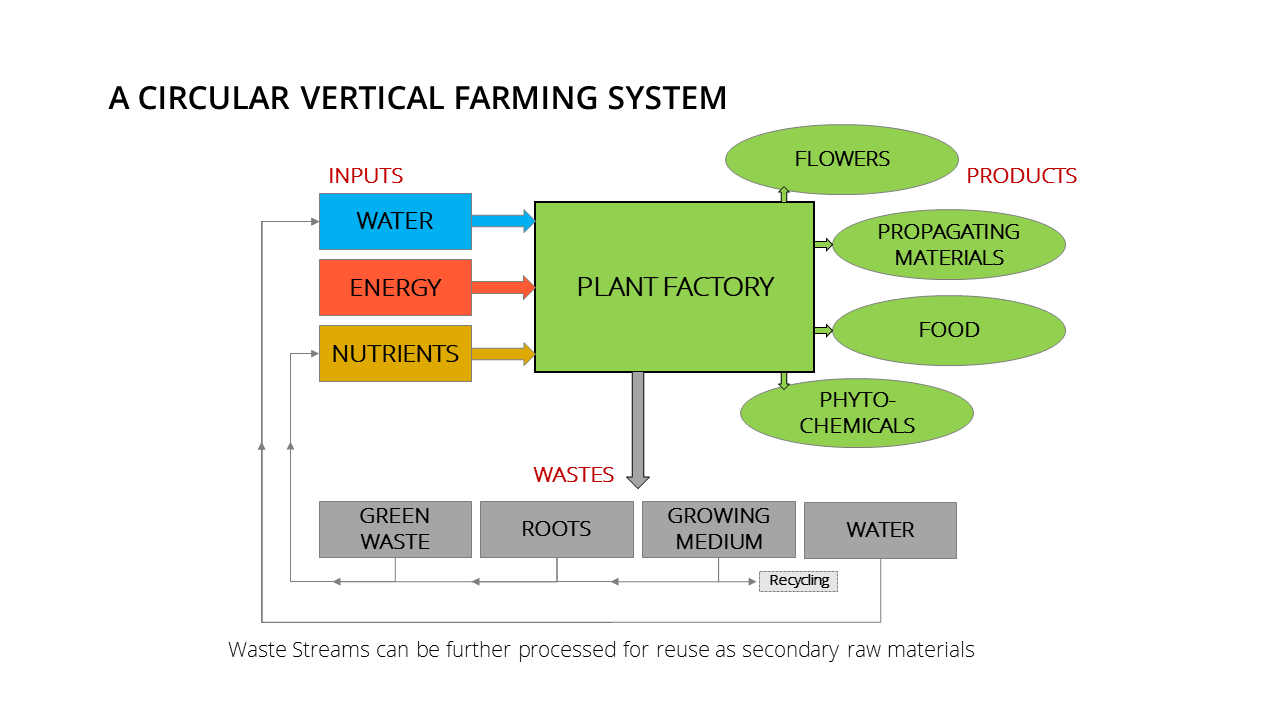

Applying their knowledge of biotechnology and phytotechnology, Biopolus has spent the past 8 years developing a circular vertical farming system. During this time, Biopolus worked with various partners and took part in several pilot projects to develop a plant factory solution, which can connect to and transform the larger urban food system.

The urban metabolic pathways of water, food, energy, and waste are all interconnected in a series of nested networks that combine to formulate the essence of a city. While working on their patented water treatment technology, Biopolus became involved in exploring water-based urban circularity and the technologies that can be developed, not only as complementary additions to its water-treatment system, but also as individual solutions to enhance urban sustainability and circularity. Biopolus has created a circular vertical farming system, to create a resilient and sustainable method of urban farming.

As a circularity solution provider, Biopolus works closely with clients and partners to adapt and develop its plant factory solution to meet specific needs and to connect to new/ existing infrastructure and into new/ existing circularity loops.

H2020 SMEI Phase1 (2014 – 2015) While developing the idea of circular urban water-based networks, Biopolus began to explore the possibility of creating a controlled environment urban plant plant production facility that could stand alone or be integrated into other urban circular systems. As a first step in realizing this concept, Biopolus successfully completed an SME Instrument Phase 1 project (no. 651643) in 2014-2015, where they carried out a feasibility study and a profound market analysis. The results confirmed an interest in this type of solution and reassured the team that there was a strong enough business case to continue with further developments.

LIVINGISLAND PLANT FACTORY (2016 – 2018) Encouraged by early testing and feasibility results, Biopolus – in a strategic cooperation with the Budapest Waterworks – built a modular container facility in central Budapest with a 70 m2 net cultivation area for experimentation and demonstration. A controlled urban farming factory system, called aero.green was developed, which integrated a mixed system of three primary urban farming techniques: hydroponics, nutrient film technology (NFT), and aeroponics.

The prototype and test facility worked to gather experience and data for a next stage commercial size demonstration unit. The facility was scalable and customizable, with optimized growth modules for around 60 plant types. A specialized feeding and lighting schedule (with ideal wavelengths and intensities) was formulated for each crop, in order to create the highest quality product.

BIOPOLUS – TUNGSRAM Cooperation (2019 – Present) In 2019, Biopolus partnered with Tungsram Agritech in a mutually beneficial professional cooperation and joint business action plan in order to achieve a strong market position in the urban plant factory business.

A 150 m2 commercial demonstration plant factory with a designated R&D center was built by Tungsram Agritech in one of their unused factory halls. The facility was developed using Biopolus biotechnology and the experience gained during aero.green development. Tungsram agritech manufactured the growth chambers of the facility using their own agritech lighting and associated technology. The implementation of the facility was partly supported by the ITM Industry 4.0 program and was officially opened May 5, 2021.

The primary task of the demonstration plant and development center is to create the technological bases of a standardized and modular system, including hardware, software, and cultivation technology elements, as well as the operation and maintenance support services of future systems. A three-party cooperation was established in August 2020 with Eisberg’s Hungarian subsidiary to launch a new micro-green product line. The facility will be used to grow various plant products for Eisberg, one of the largest producers of ready-to-eat salads in Central and Eastern Europe.

This project is an ideal example of how cities can reinvent urban spaces, integrating food production into unused areas, creating a more resilient and self-reliant food chain.