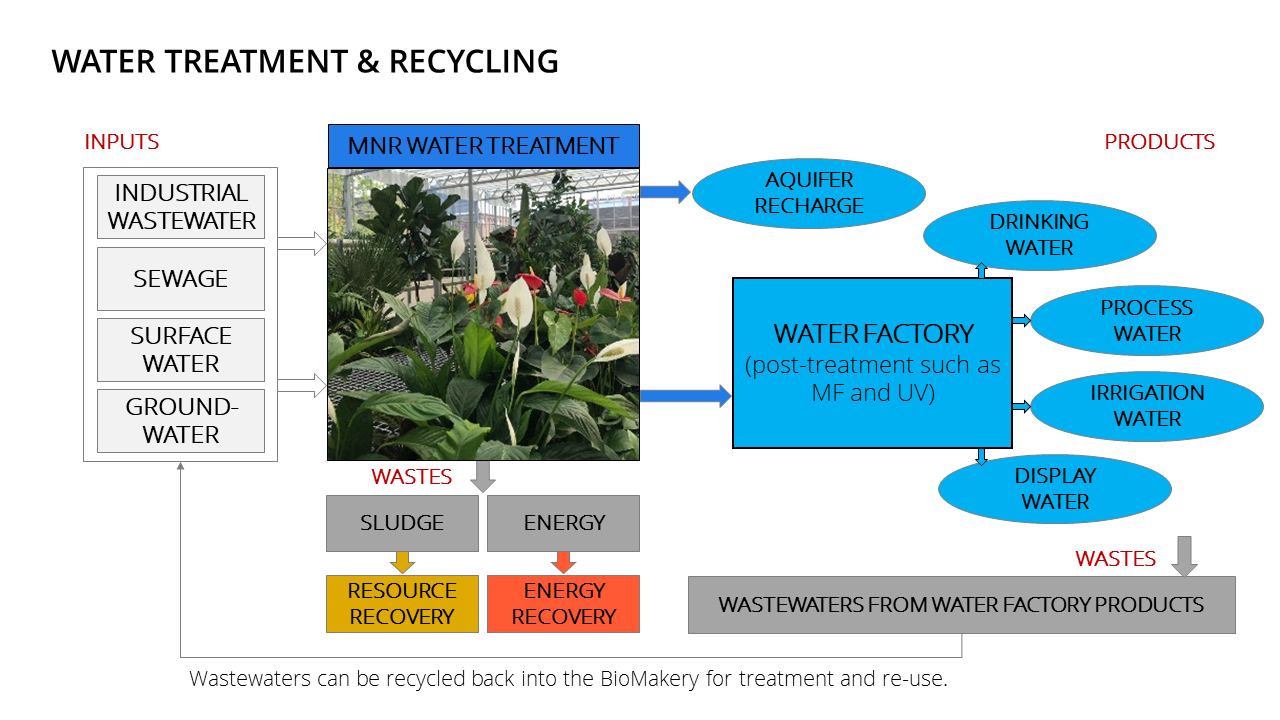

Biopolus’ water-based urban circularity revolves around using nature-based solutions to bioengineer a sustainable water cycle. The solutions are housed in a beautiful greenhouse environment where water can be ‘reborn’ to be used over and over again.

Biopolus’ modular, expandable water treatment system uses complex circular urban water treatment and management to maintain our most valuable natural resource for future generations to come.

Wastewaters from industrial processes, commercial and residential developments, and even urban waterbodies can be treated to the most stringent regulations, perfectly safe to be released back into the environment. However, by adding post treatment processes, the water can be given new life and recycled back into the community in the form of a variety of water products.

Because the water treatment takes place locally in a beautiful greenhouse environment (BioMakery), using Biopolus MNR technology, it can stay local and be reused more effectively.

The Metabolic Network Reactor (MNR) technology is Biopolus’ patented 3rd generation Integrated Fixed-film Activated Sludge (IFAS) water treatment technology.

The underlying principle behind the MNR technology is a well-known natural phenomenon, where microbial biofilm develops on the roots of aquatic plants. The technology is characterized by a large quantity of biomass that is attached to submerged „carriers” – either to the natural root system of specially selected plants, or to artificial roots, developed by Biopolus, for this specific purpose.

BIOLOGICAL WASTEWATER TREATMENT

Biological wastewater treatment is a common treatment method, that uses different types of microorganisms to treat and purify polluted water. In creating the Metabolic Network Reactor (MNR), Biopolus has optimized this natural phenomenon, and through smart design, developed a technology to maximize the efficiency of microorganisms to degrade organic waste.

The full treatment process takes place in an array of MNR reactors. This separation makes it possible to fine-tune the environmental conditions in each section, allowing for the development of separate, specialized ecologies to mature in the different tanks. As the water flows from reactor to reactor, it is continually cleaned, as various species break down the different contaminants. The path and volumetric distribution of wastewater between the reactors is controlled by process management software and can dynamically adapt to the changing loads, thereby optimizing the process.

ARTIFICIAL ROOTS

The artificial root structures developed by Biopolus, mimic natural plant roots, maximizing the surface area to which microbial communities can attach. This environment is ideal for the development of a complex microbial biofilm, enabling optimized water treatment. These structures are made of specially designed patented textiles custom-made for Biopolus, and attached to injection molded plastic frames, in particular formation, for maximum efficiency.

MODULAR SOLUTION FOR ANY URBAN ENVIRONMENT

The MNR reactor technology was designed to be modular and expandable, where the system can be scaled to the desired size, and arranged in a vertical or horizontal layout for maximum architectural flexibility. The facility that houses the MNR technology, the BioMakery, can integrate water treatment and recycling with a wide range of other functions including: biological manufacturing, food production, energy recovery technologies, and community functions, to become a true hub for urban circularity. Odor free, compact, and modular, the BioMakery with its garden-like atmosphere, can placed into any urban environment through creative architecture.

MUNICIPAL WASTEWATER

Wastewater is treated to the most stringent regulations, perfectly safe to be released back into the environment, or with additional processing, the water can be reused in several ways including: irrigation water, display water, and/or process water for heating or cooling systems.

INDUSTRIAL WASTEWATER

The modularity of MNR technology allows it to be designed to treat the industrial wastewater of various industry types including food & beverage, textile, and electronic industries. The solution is tailor-fit to handle the various contaminants of the influent, however a requirement for MNR technology is that there are no barriers to biological treatment. Depending on the influent type, MNR treatment may be supplemented with pre and/or post processes in order to treat the water to reuse quality.

URBAN WATERBODIES

MNR technology can be used to treat, rehabilitate, and maintain healthy urban waterbodies such as natural lakes, artificial ponds, decorative fountains, groundwater, and canals. The system boosts the natural self-cleaning mechanism of these waterbodies, helping to prevent eutrophication and contamination when contamination loads from urban pollution and agricultural runoff are high.